Breakthrough in Novel Green Synthesis Process! Megastigmatrienone Expands New Dimensions for Fragrance Applications

Recently, the fragrance and chemical industry has witnessed exciting technological progress — significant advancements have been made in the research on green synthesis processes and quality optimization of megastigmatrienone, a natural aroma compound. Its unique aromatic value and application potential have been further unleashed, providing new support for product upgrades in industries such as daily chemicals and food.

As a carotenoid degradation product, megastigmatrienone naturally occurs in various plant materials. It is renowned for its intense and long-lasting sweet, warm, and dry aromatic characteristics, accompanied by a soft spicy undertone, making it a core component in constructing natural-style fragrance systems. Previously, large-scale production of this compound was limited by challenges such as difficult raw material acquisition, complex synthesis processes, and environmental pollution. However, the newly developed synthesis technology has successfully addressed these issues. The new method uses easily available α-ionol acetate as the raw material, adopts a composite catalytic system of N-hydroxyphthalimide and dibenzoyl peroxide, and produces the target product through steps including air or oxygen oxidation and reactive distillation. Compared with traditional processes, this technology not only reduces raw material costs by over 30% but also enables the recycling of solvents and catalysts, significantly reducing waste discharge — a veritable green innovation in the field of fragrance synthesis.

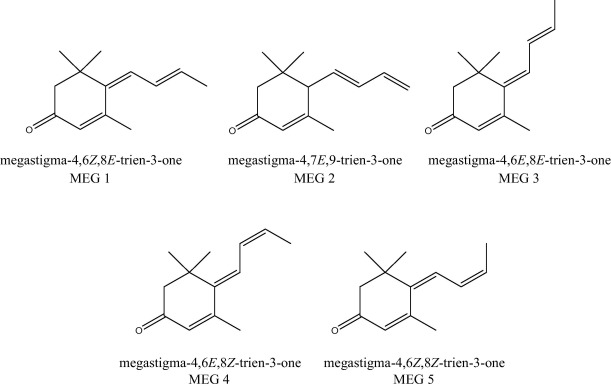

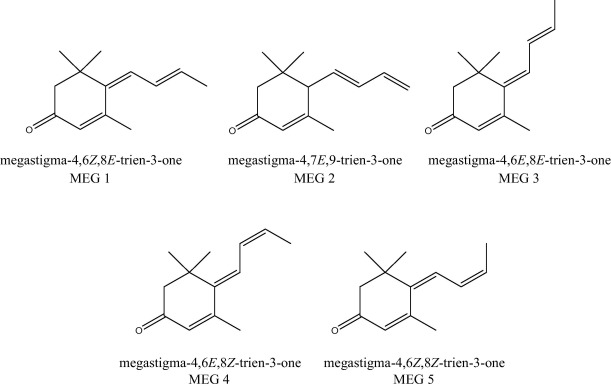

In terms of quality optimization, the alkali-controlled technology developed by the research team offers a new approach to enhancing the aromatic efficacy of megastigmatrienone. Through precise alkali-added heat treatment and acid neutralization processes, the proportion of its active isomer D can be effectively increased, with the ratio of isomer D to B exceeding 85%. Additionally, the storage stability of the regulated product has been greatly improved. Experiments show that the optimized megastigmatrienone exhibits a richer aromatic layering, with its fragrance retention time extended by 40%, and its fragrance-enhancing effect is significantly superior to traditional products.

Leveraging its excellent aromatic properties and technological breakthroughs, the application boundaries of megastigmatrienone are continuously expanding. In the daily chemical industry, its warm and mellow aroma has been widely integrated into high-end perfumes, body washes, and hand creams. It imparts a natural and fresh base to formulations while achieving harmonious blending with various fragrance types. In the food fragrance industry, it can be used in flavoring baked desserts and fruity beverages — a small addition can enhance the fullness and authenticity of flavors. In household care products such as scented candles and air fresheners, its unique warm aroma creates a comfortable and soothing spatial atmosphere, making it a popular raw material amid the trend of consumption upgrading.

Industry experts point out that this technological breakthrough in megastigmatrienone not only solves long-standing production challenges but also fully taps into its natural aromatic value. As the green synthesis process is industrialized, this compound will inject new vitality into product innovation across industries with higher cost-effectiveness and more stable quality, driving the fragrance industry to accelerate toward greenization and high-quality development. Currently, the relevant technology has entered the industrialization stage, and the first batch of food-grade products has opened the sample trial channel.